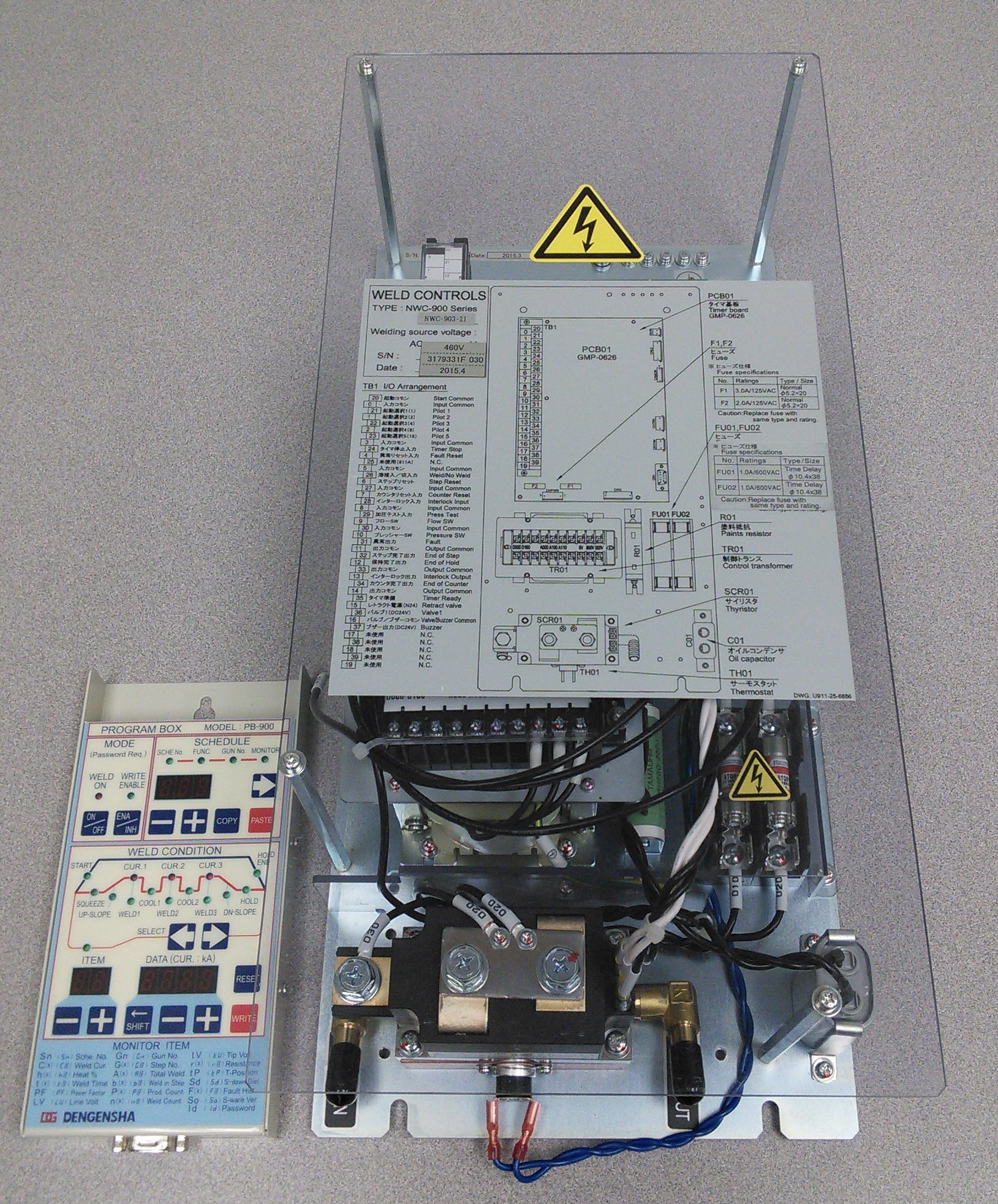

Our sophisticated control systems can network up to 100 sets of welding controls that link directly to your PCs and printers. Displays are graphically enhanced to allow you to grasp the welding conditions at a glance and see various data at any time. The range of weld current to monitor can be set in percent and a limit value for each sequence can be set as well.

Safety and protection functions are built in, including limiting the number of stops, preventing rewriting of the program, and protection switches for “spotless” and data memorization functions. With the maintenance-free, super-capacitor feature, you eliminate the need to change batteries.